Modern construction can only function properly with precision and accuracy. This feat is only achieved through accurate bar bending of the TMT bar. Moreover, incorporating a Bar Bending Schedule ensures the strength and stability of structures by reinforcing concrete. To increase the precision and strength of a construction, this process involves. Bending of steel TMT re-bars or a reinforced TMT bar to precise shapes and angles. This enables better structural design as well as letting the TMT bar absorb tensile forces.

Accurate bending of steel TMT bar is the key to making a construction work better in every way. It makes the project cost-effective as well as reducing unnecessary construction waste. Furthermore, accurate bar bending also speeds up the construction project. This happens due to accurate measurements, which leads to minimum errors. S-E-L Tiger knows the importance of bar bendings and that is why, our TMT bar has been the number one choice of engineers. In this blog, let us share the importance of accurate bar bending in any type of modern construction project.

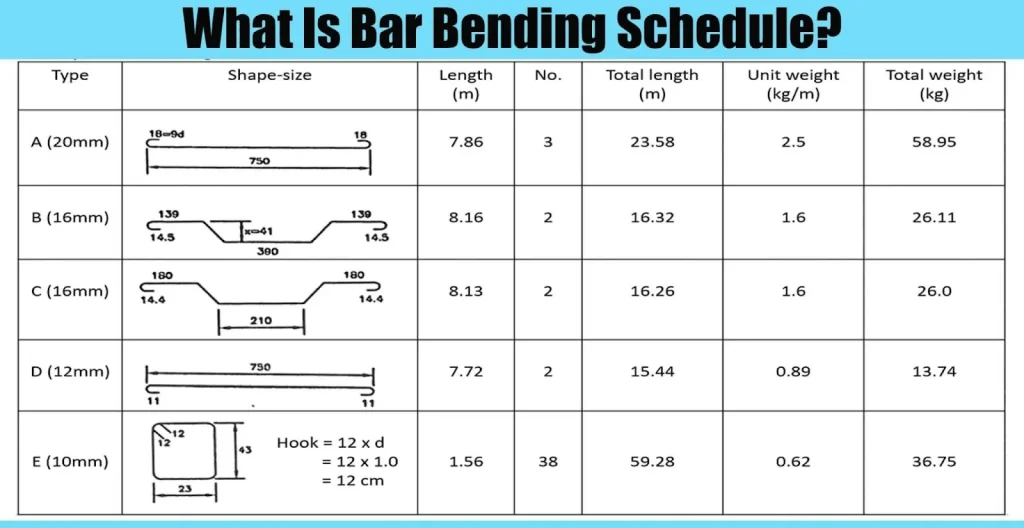

In the civil engineering sector, the Bar Bending Schedule is known to be a road map for various construction projects. It is basically a document that has a long list of all types of reinforcement TMT bars that must have specific shapes and dimensions. Furthermore, it contains the specific types of bar bending that are needed for the construction work. BSS speeds up the preparation time as well as the construction process.

The work of the Bar Bending Schedule is to bring an engineer’s theories to an actionable stage. It breaks down complex structural design into structures that can be used practically, like steel fixers and bar bending. BSS is very useful in various construction projects like in off-site preparation. It also ensures on-site safety measures by reducing cutting and bending resulting in less congestion in the construction site. TMT bar by S-E-L Tiger brings this ideal reinforced structural design to reality.

Moreover, BSS is also useful for reducing wastage by providing exact measurements and quality of materials. It helps in cost-saving and maintaining sustainable construction work. Additionally, because of accurate management, changes in errors are reduced. Especially, structural integrity is increased due to better quality control. BSS after all, serves as a perfect reference point for ensuring quality checks. Thus, the Bar Bending Schedule serves as an integral part of construction work.

Source: sreemetaliks.com

TMT bar is known to absorb tensile force better than concrete. Concrete remains stable under strong compression but they are weak against tension. Thus, TMT bars that are properly bent, distribute high load correctly throughout the structure. But remember, if any inaccuracy occurs in the measurement, it can cause a compromise in the structural integrity of the project. Because weak points develop due to misalignment.

As we have mentioned before, BSS helps in bringing ideal engineering design to real applications. Also, engineers design structure specifications depending on the type of project. These specifications are set by keeping by how much load a TMT bar can handle. As you already know, BSS outlines specific procedures by how much TMT re-bar should be bent to meet these requirements. Remember, miscalculating the prescribed angles of bend can affect the structural integrity of a building, leading to safety hazards.

Following the prescribed process by engineers, proper measurement of materials leads to less wastage. Furthermore, accurate bar bending can be achieved by using modern machines. These machines accurately bend the TMT bar which leads to fewer errors, less wastage and fast construction work. It also helps in minimizing cost overruns and delays in the construction schedule. Accurate bar bending is extremely important to large-scale projects. Because inefficient use of materials or small errors in bending can lead to significant financial losses.

i) Safety Assurance: One of the biggest reasons for doing accurate bar bending is to ensure safety. Error-filled bending of a TMT bar can lead to an unstable structure. This increases the chances of failure of the buildings. The risk even increases further for high-rise buildings, bridges, or other critical infrastructure. Thus, to avoid this predicament, it is advisable to precisely follow the design. This not only eliminates any hazard but also prologues the lifespan of the buildings.

ii) Increasing Longevity Through Load Distribution: Re-bars are bent into various shapes like stirrups, links, and ties. Such accurate bending gives strength and durability to the structure. Furthermore, by correctly being bent in specific areas of the overall structure. The bent TMT bar helps in proper load distribution. This ultimately helps in reducing the chance of failure in various elements like beams, columns, and slabs. Thus, successfully resisting stresses and strains imposed over time. The likelihood of cracks or fractures in the concrete is also greatly reduced.

ii) Compliance with Building Codes: Governments set standards for building through Building Codes. Building codes and standards such as IS 456 (Indian Standard for plain and reinforced concrete) or BS 8110 (British Standard for structural use of concrete) mandate specific guidelines for re-bar bending. Thus, accurate bending is necessary to ensure compliance with these codes. Because it is essential for passing inspections and gaining approval from regulatory bodies for the projects.

So, at this point, it is pretty clear how much accurate bar bending is important to any construction project. Giving structural integrity to any building project by making sure it can withstand any stress. Following the Bar Bending Schedule precisely leads to greater load distribution. Which helps in reducing cracks and other problems that often take place over a long time. Furthermore, for constructors, it is a perfect way to save up on budget as it eliminates any chances of errors as well as wastage of costly construction materials. Lastly, it helps to speed up the project itself. S-E-L Tiger manufactures some of the leading TMT bars that bend precisely and give any structure stability.