Have you ever wondered how many types of TMT bars there are that give structure stability? Do properties change depending on the TMT bar sizes? One of the fundamental contributors to a construction’s structural stability is beams. They give necessary support loads, provide rigidity, and ensure the integrity of a building’s framework. But, the beams also have different types that perform different tasks. Among these types, we have the Tie beam and the Plinth beam. In this blog, we will focus on differentiating between Tie beams and Plinth beams and knowing which sizes of TMT (Thermo-Mechanically Treated) bars are suitable, which is crucial for effective and safe construction.

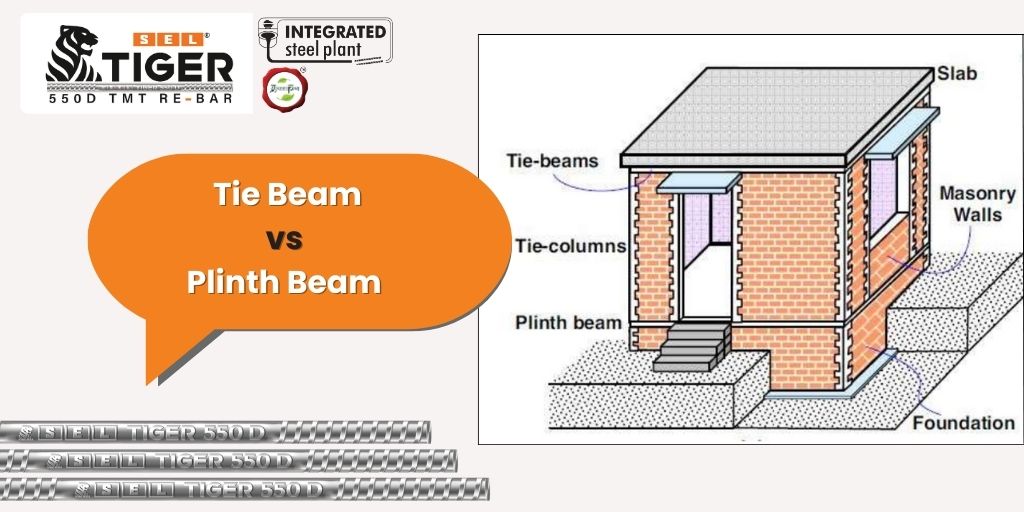

A tie beam is basically a structure of TMT bars that are arranged horizontally and connect two or more columns to reduce the risk of buckling. They are mainly used in higher elevations where they prevent lateral displacement of the columns and improve the stability of the structure. By doing this they drastically reduce load on the footing by evenly distributing the load across the structure. Moreover, tie beams are capable of withstanding tensile forces that arise due to the differential movements or settlement in the building.

Furthermore, they are also capable of withstanding earthquakes by providing additional stability to the structure and overall framework. The TMT bar sizes of a typical Tie beam usually depend on the type of the building. But on average they are 12mm to 20mm in diameter and come in higher grades like Fe 500 or Fe 550. The size of the diameter mainly depends on the load intensity, column spacing, and construction type as mentioned earlier.

Tie Beam Structure

Like a tie beam, a plinth beam is also a horizontal structure but provides support at the plinth level or at the foundation of a building. The plinth beam sits right above the ground level which provides load-bearing support directly, something that the tie beam does not. They distribute the load across the foundation evenly. Plus, plinth beams support the wall of the building. They do this by distributing wall loads to the foundation, preventing the differential settlement of walls. Furthermore, the reinforcement prevents any type of cracks from taking place in the walls.

Similar to the tie beam, the plinth beam is also capable of resisting seismic activities by providing lateral support. Finally, the plinth beam gives a strong base of elevation above ground level. This arrangement helps to protect the building from water seepage and soil erosion. The determination of the TMT bar sizes of the plinth beam largely depends on the design of the the load and what type of soil it is built upon. But on average, we have 10mm to 16mm diameter TMT bars that are commonly used with a similar type of grade that is seen in tie beams.

Plinth Beam Structure

To start off with, the location where they provide support is different, Tie beam is found on the higher levels of a building’s structure. Where they distribute the load evenly across the whole upper portion of the structure. Whereas, a Plinth beam is located at the plinth level or at the foundation level which is right above the ground level. Here they provide support to the building structure from the base level.

Furthermore, in the load-bearing department, a tie beam is capable of resisting any kind of lateral displacement. This gives a construction the needed structural integrity. Furthermore, such load-bearing capacity gives tie beams resistance to earthquakes. On the other hand, a plinth beam provides necessary support by directly bearing and distributing the load exerted by the wall. Moreover, plinth beams are capable of giving additional structural integrity during seismic activities.

Tie beams to connect with the columns and prevent buckling, need to have an average diameter of 12mm to 20mm of TMT bar size. They need to be strong given their job, so nothing less than Fe 500 or Fe 550 grade of TMT steel can be used. As for the plinth beam, the TMT bar sizes has to be between 10mm to 16mm in diameter with a grade of Fe 500 or Fe 550. Without this specification, a plinth beam will not be able to provide support to the walls, distribute loads, and prevent settlement.

Choosing the right TMT bar sizes is very crucial when constructing any kind of building or structure. Each type of construction has its own unique design and quirks that need a specific type of TMT bar size and grade. Remember, there are a variety of TMT bar grades to choose from like Fe 415, Fe 500, Fe 550, and Fe 600.

In the case of tie beams and plinth beams, Fe 500 and Fe 550 are most commonly used. This is because the pressure that these beams handle needs stronger TMT bar steel with average TMT bar sizes of 10mm to 20mm in diameter. Moreover, higher-grade TMT bars offer better resistance to corrosion and heat which is needed to increase the longevity of a structure.

With over two decades of experience in manufacturing one of the best TMT bars in India. We have been providing the best TMT bars to different industries with flawless performance. The TMT bars for tie beams and plinth beams we deliver are strong and can withstand any type of pressure, seismic activities and high load. We offer a variety of TMT bar sizes that are suitable for structures like homes, apartments, skyscrapers, bridges and many more. Our brand provides confidence in our customers to make the best architectural marvels!

Both tie beams and plinth beams are integral to ensuring a building’s stability and longevity. While tie beams mainly reinforce columns to reduce buckling and lateral movement, plinth beams provide foundational support for walls and distribute loads evenly. Selecting the appropriate TMT bar sizes, typically 12mm to 20mm for tie beams and 10mm to 16mm for plinth beams, and opting for Fe 500 or Fe 550 grades are essential steps to achieving a strong, resilient structure. After all, selecting the right material is one of the most essential parts of any construction project.